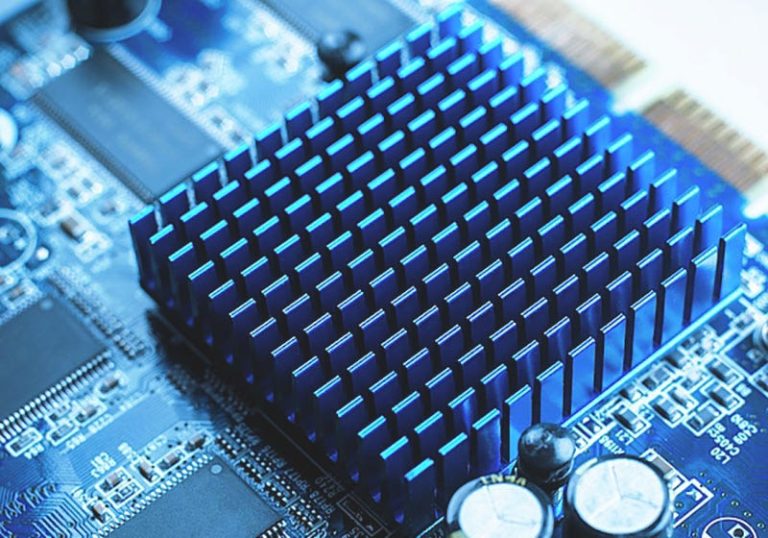

Warmth sinks are essential in digital units as they assist dissipate warmth generated by varied digital parts corresponding to processors, energy provides, and different high-power units.

By integrating machine vision-based warmth sink detection into the manufacturing course of, electronics producers can enhance the reliability, efficiency, and security of their merchandise, whereas additionally enhancing their total high quality management and manufacturing effectivity.

Intsoft Expertise has documented the method of detecting warmth sink defects as follows.

Measurement of detected merchandise: Size 42.55mm / Width 18.5mm / Excessive 11.5mm, floor detection, dimension measurement

Detection content material:

1. Facet constructive gentle detection measurement

2. Facet constructive gentle inspection look

3. High constructive gentle detection measurement

4. High constructive gentle inspection look

5. Backside constructive gentle inspection look

6. Backside constructive gentle inspection look

7. Facet constructive gentle detection measurement

Word: The above inspection objects have to be clearly seen below the picture to be detected.

Inspection effectivity: 50–100 items per minute (in keeping with pattern feeding velocity).

Segmentation: Subdivision of inspection steps in keeping with inspection content material.

General Composition Measurement:900*800*1850 mm

Mannequin:INTSOFT_302C

1. INTSOFT Visible Inspection Software program

2. Industrial pc

3. 19 inch Show

4. Industrial digital camera: 6 units, respectively, the highest of the detection pins crooked, oxidation, left aspect of lacking elements, proper aspect of lacking elements

Facet backlight detection pins crooked, backside detection oxidation, lack of pins, backside detection of international matter between pins.

5. Industrial lens: 5 units of FA industrial digital camera, 2 set of telecentric lenses

6. Skilled glass disk

7. Solenoid valve

8. Reducer

9. Vibration machine

10. Feeding tools (vibration disc, electro-vibrating feeder, controller).

Facet detection unique picture:

Facet detection good product evaluation picture: OK

Facet detection faulty product evaluation picture: NG

Facet detection unique picture:

Facet detection good product evaluation picture: OK

Facet detection good product evaluation picture: NG

High detection unique picture:

High detection good product evaluation picture: OK

High detection unique picture:

High detection faulty product evaluation picture: NG Reason behind defect: Stain, scratch

High detection faulty product evaluation picture: NG Reason behind defect: Stain, scratch

Backside detection unique picture:

Backside detection good product evaluation picture: OK

Backside detection faulty product evaluation picture: NG Reason behind defect: Tilt

Backside detection unique picture:

Backside detection good product evaluation picture: OK

Backside detection faulty product evaluation picture: NG Reason behind defect: Edge burrs

Facet detection unique picture:

Facet detection good product evaluation picture: OK

Gear positioned within the inspection area: Within the meeting line aspect of the set up of Intsoft imaginative and prescient inspection system alone, you must guarantee that there’s sufficient area to put in the tools.

Ambient temperature: 0–50 levels Celsius;

Air humidity: 90% RH or much less;

Digital interference: Present a spot with much less digital interference for the tools.

Energy provide: AC 220V, 50Hz, Energy consumption <1KVA, Air strain 0.35 ~ 0.7MPa

The above is the USB socket machine imaginative and prescient inspection program. In case your industrial manufacturing line wants imaginative and prescient detection know-how, don’t hesitate to speak to Intsoft Expertise, we offers you probably the most skilled recommendation.

Reprinted from https//:intsoft-ai.com