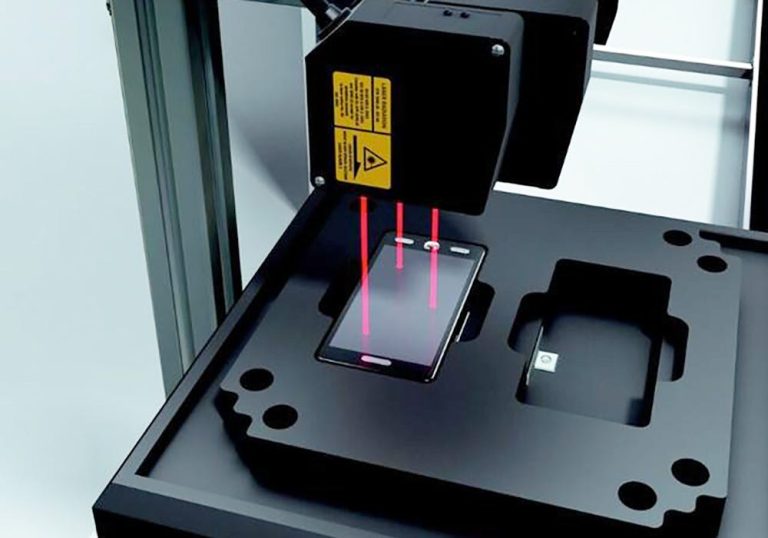

Mission: 3D imaginative and prescient cell phone case defect detection

Class: Machine imaginative and prescient product software

Within the subject of machine imaginative and prescient, 3D imaginative and prescient is nearer to the human eye. Along with seeing objects, it might probably additionally get hold of depth data of objects and might understand multi-dimensional positioning and recognition, so it’s extra well-liked. 3D imaginative and prescient expertise integrates synthetic intelligence to permit industrial robots to suppose like human brains to carry out high-precision and complicated work.

Conventional imaging methods are based mostly on two-dimensional planes, so conventional visible methods put issues that should be detected or measured on a flat picture to unravel; however the actual world is three-dimensional, and conventional two-dimensional visible methods have many issues which are tough to attain, reminiscent of built-in pins, obscured elements, description of curved surfaces, and so on. However utilizing 3D visible inspection methods can simply deal with them.

The imaging subsystem of the 3D visible inspection system is equal to a row of level laser rangefinders to acquire the cross-sectional information of the thing being measured: the evaluation subsystem reconstructs the three-dimensional data of your entire object being measured by a set of cross-sectional information obtained synchronously with the movement system encoder. The system {hardware} helps micron precision. As well as, our 3D visible inspection system software program leverages {hardware} efficiency, 3D modeling, 3D spatial evaluation, and offers varied 2D evaluation instruments and third-party evaluation software program interfaces.

Intsoft Expertise can nicely picture the contour and form of cell phone circumstances. The algorithm used is the flatness measurement device built-in inside Intsoft Expertise, which offers good uncooked information for measuring the floor of cell phone circumstances.

Scanning shiny or reflective surfaces, arrange three sensors to type a multi-sensor measurement community, and sew the information right into a single 3D picture after scanning. Multi-sensor calibration perform. After calibration, synchronize scanning and stitching, flatness 10 instances static repeatability 0.002mm

By splicing 2 sensors, floor flatness is measured and attainable dents are detected. Twin sensors detect the goal object, decrease the scanning blind space, improve the scanning subject of view, and preserve excessive decision over a large subject of view. Flat repeatability 10 instances 0.002mm.

Reprinted from https://intsoft-ai.com